Rocket launcher

Materials for the launcher:

- PVC pipe - needs to be a fraction less than 21.5mm outside diameter, for the bottle neck to slide smoothly during launch but still a good fit

- a 22mm tee piece compression joint

- a 22mm end cap for the above compression joint

- another 22mm end cap, this time to seal the end of a 22mm pipe (not the same as the item above)

- a spare 22mm compression fitting nut.

- some 40mm waste pipe

- PTFE tape

- a wire coat hanger

- cable ties

- a car type valve

STEP 1

Insert the pipe you are going to use as the launch tube into a PET bottle. Mark the point at which the bottle will launch from on the pipe. Measure 15cm from the neck of the bottle, down the pipe and cut.

STEP 2

Make a small groove around the launch pipe using a hacksaw at the point you want the rocket to sit prior to launch, i.e.. 16cm from the bottom end of the pipe The groove should be no more than 0.5mm deep.

The groove is designed to hold the PTFE tape in place, which will act as a gasket to seal the bottle while it is being pressurised for launch.

Now wrap PTFE tape around the groove for a few turns.

STEP 3

Check by sliding the bottle into place, that you have just enough PTFE tape to ensure that the neck of the bottle will seal when it is pushed fully over the tape.

STEP 4

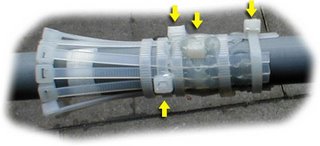

This is the slightly tricky part. a little below the point where the bottle mouth will sit (on the PTFE tape) hold several cable ties around the pipe. The cable tie heads should be facing towards the pipe (see diagram). Use enough ties, so that the heads of the cable ties are against the pipe and touch each other at the sides. Loosely cable tie these ties to the pipe. I have used three cable ties to secure the launcher ties.

STEP 5

Now push the bottle into place over the PTFE tape, to the point on the tube where the bottle will launch from.

Pull each of the cable ties up one at a time so that the tie heads sit over the lip on the neck of the bottle.

STEP 6

With all the launcher cable ties in place, tighten the cable ties that are around the tube, in order to hold everything in place.

STEP 7

Trim the ends off the cable ties around the pipe and if necessary add some extra cable ties around the tube. I used three more. One is underneath. These all help to clamp the launcher ties in place.

Then use hot melt glue to further hold the launcher ties in place.

STEP 8

Trim the launcher ties.

It will probably be necessary to file down the heads of the clamping cable ties.

This will allow the locking collar to easily slide over these Cable tie heads.

STEP 9

To make the locking collar use 40mm waste pipe. Cut two pieces, one about 7cm long and the other about 9cm long.

- cut a slit down the full length of the longer, 9cm piece of pipe

- spread the slit in the longer pipe so that it pushes over the shorter one. The top part of the longer split tube is the right diameter to lock the cable ties in place around the bottle neck, while the rocket is being pressurised.

- turn the locking collar over and glue a nut from a 22mm pipe fitting into the bottom section.

- slide the collar up over the pipe to make sure it fits OK.

STEP 10

Once the collar slides on the pipe reasonably loosely, remove it again and drill two holes about 0.5cm above the 22mm pipe fitting nut you glued in earlier. One of the holes is shown in the picture, the other is on the opposite side.

STEP 11

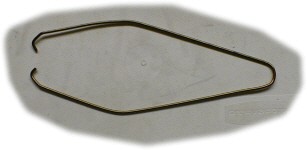

Take a wire coat hanger and cut it to size using a pair of wire cutters. Straighten it out using a pair of pliers.

STEP 12

Bend the wire coat hanger into the shape in the picture bellow.

STEP 13

Now carefully push the hooked ends of the wire into the holes in the collar.

STEP 14

This is the spring mechanism. It is designed to hold the locking collar in place before launch, whilst the rocket is being pressurized.

Cut it from the middle of a small half litre coke bottle. Then cut two holes, just large enough (22mm) for the launch pipe to go through.

STEP 15

Slide the locking collar back onto the launch pipe and slide the retaining spring behind it.

STEP 16

The pressure valve (car tyre valve) is attached to a 22mm end stop. The end stop comes with a rubber seal/washer inside, you will need to remove this seal. Now drill a small pilot hole in the center of the cap. This hole will need to be successively increased to 14mm in diameter. Put plenty of hot melt glue inside the end cap and firmly push the valve through. Once cool screw the cap onto the tee joint. Use extra hot glue and/or PTFE tape to ensure the integrity of the joint is maintained under pressure.

STEP 17

Now slide the 22mm compression pipe fitting behind it and using PTFE tape make the joint.

STEP 18

Now attach another 22mm pipe to the bottom of the 22mm tee joint and attach a 22mm end stop to the other end of this pipe.

STEP 19

You will need a wooden stake (about 22mm diameter), four 22mm plastic pipe clips and a couple of wood screws.

Place two plastic clips on the wooden stake just far enough apart to allow you to clip the launcher to the stake (yellow arrows).

Drill two small pilot holes into the wood, through the attached clips fixing hole.

Screw the remaining clips onto the stake through these fixing holes.

No comments:

Post a Comment